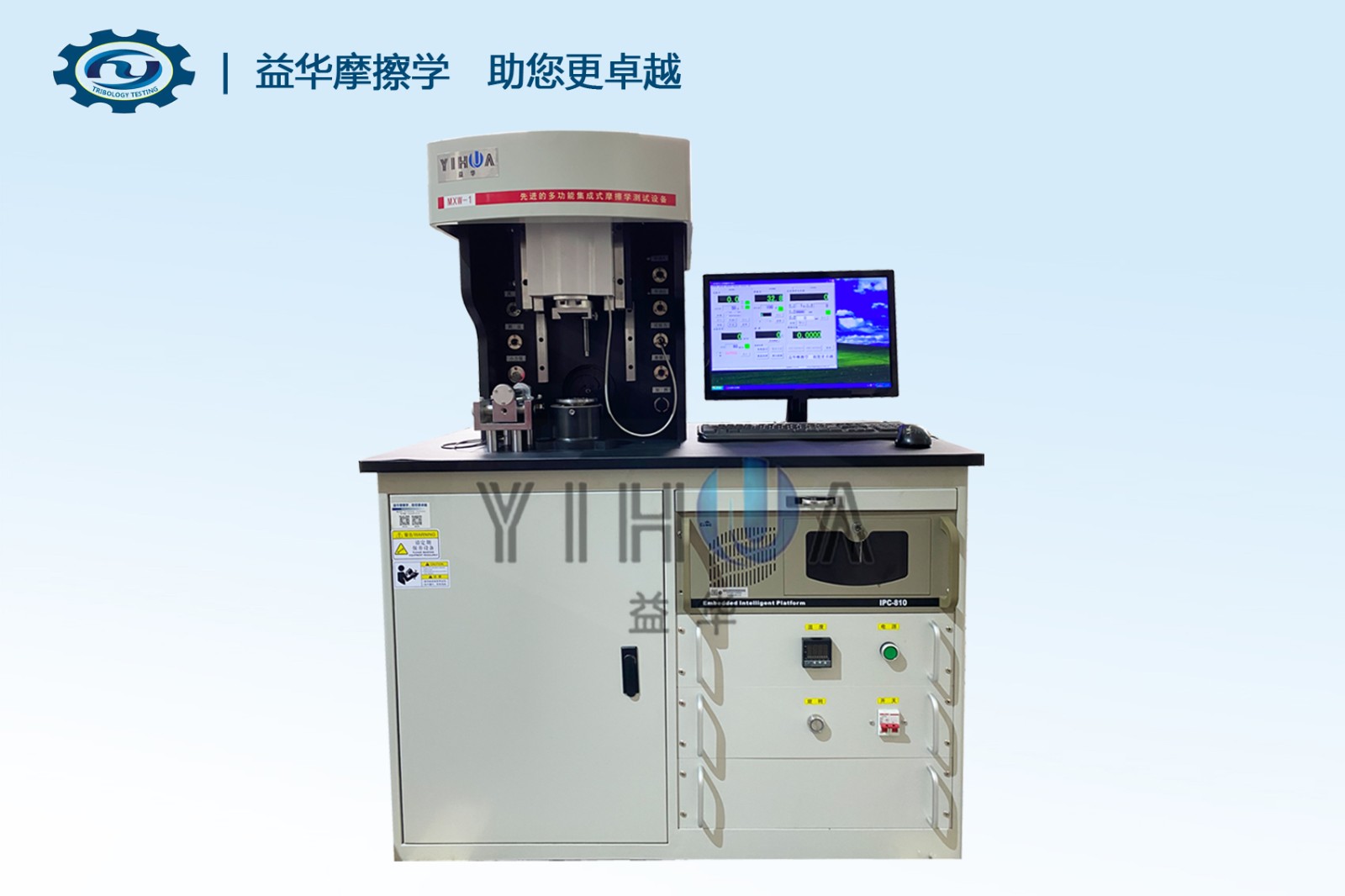

济南益华摩擦学测试技术有限公司是国内第一家专业从事摩擦学测试技术研究及试验仪器、试验设备开发的公司。是一家集科研、生产、销售、技术服务、学术交流于一体的高科技企业。我公司是国家摩擦学学会的会员单位。拥有国内一流的摩擦学测试技术研究、开发的专家和科技人员。具有强大的技术创新能力,丰富的专业理论和实践经验,覆盖全国的营销网络,有自己独特的企业文化。

产品及解决方案

PRODUCTS AND SOLUTIONS

走进益华

ABOUT US

委托实验

ENTRUSTED EXPERIMENT